Logistics Manager’s Index Posts a Strong June Reading

By: Logistics Management

After nearly two years of soft conditions, the June 2025 Logistics Managers Index (LMI) posted its highest reading since early 2022, clocking in at 55.6. The LMI — a leading indicator that tracks trends across transportation, inventory, and warehousing — reflects a rebalancing of the supply chain. Growth in transportation utilization and inventory levels, along with rising warehouse activity, suggests that demand is returning to more typical patterns. This shift indicates that companies are restocking inventories and preparing for greater throughput, likely in anticipation of back-to-school and holiday seasons.

However, this renewed activity also brings challenges. A tightening transportation market could lead to capacity constraints and higher costs if demand continues to climb. Meanwhile, businesses that had leaned out their operations during the downturn may find themselves scrambling to scale back up. The LMI’s rebound is a signal to logistics leaders that agility and preparedness are critical. Now is the time to ensure operations, labor, and partnerships are ready for a more active market cycle.

CAPSTONE TAKEAWAY

A strong LMI signals opportunity; but the news isn’t rosy just yet. While there are strong signals of renewed momentum, uncertainty remains a driving factor, and logistics firms are preparing for tighter capacity and potential cost increases. As demand returns, companies must ensure they have flexible, scalable logistics partners in place to adapt quickly to shifting volumes and avert bottlenecks. At Capstone, we’re already seeing increased activity across our network, especially in final mile and cross-dock operations. By combining predictive analytics with agile workforce strategies, we help customers navigate market shifts without compromising service or cost-efficiency.

Rethinking Enterprise Yard Operations: The Rise of the Yard Operating System

By: Supply Chain Management Review

While warehouse and transportation management have seen significant technological transformation in recent years, yard operations have often lagged — until now. There is a growing trend for logistics firms to implement Yard Operating Systems (YOS), which give companies real-time visibility into what’s happening in the “in-between” space where trailers, shipments, and docks intersect. With a YOS, businesses can better coordinate appointments, streamline gate operations, monitor trailer dwell times, and ensure tighter synchronization between yard, warehouse, and transportation activities.

As supply chains become more complex and customer expectations for speed increase, the yard must also be connected to operations for efficiency’s sake. Manual, paper-based systems leave room for error and inefficiency, particularly at high-volume facilities. The rise of YOS platforms represents a shift toward fully integrated, data-driven logistics ecosystems that close visibility gaps and support smarter decision-making. Companies that invest in digitizing yard operations can reduce delays, improve throughput, and enhance safety — all while improving their ability to respond quickly to real-time changes.

CAPSTONE TAKEAWAY

The yard is no longer just a waiting room: it’s a critical control point. Inefficient yard movement creates systemic drag on OTIF and drives up costs. Capstone champions YOS adoption as part of our integrated supply chain tech stack. With embedded yard management visibility, our clients can coordinate vehicle arrivals, dock schedules, and labor in real time — and even adjust on the fly when things change. This results in lower dwell times, fewer missed appointments, and a more transparent flow of goods from yard to customer dock.

AI’s Steady Maturation in Supply Chains

By: Forbes

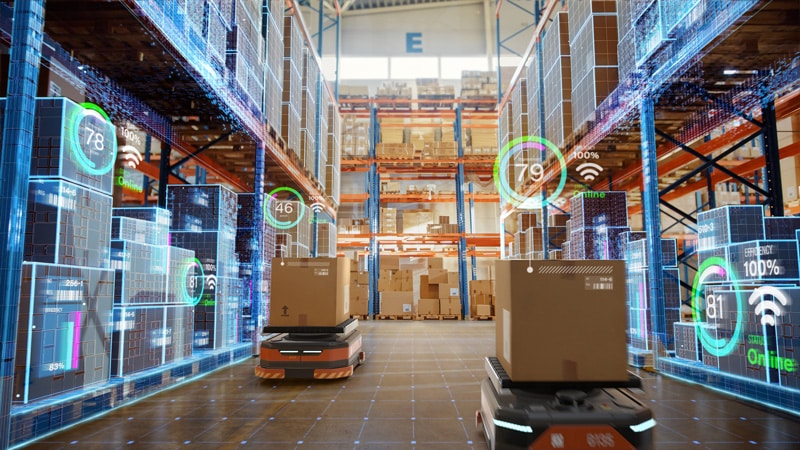

Analysts across the industry are still debating the uses and value of AI in the logistics industry; yet it’s already embedded in tools and systems across the entire supply chain. This recent Forbes article is worth reading in its entirety, but to summarize, it takes a historical look at how AI has already fundamentally changed the supply chain in the way we use data for everything from demand forecasting and inventory planning to anomaly detection and transportation optimization. These use cases are delivering measurable gains in efficiency and responsiveness, helping businesses reduce costs and better manage disruptions in an increasingly complex environment.

Yet, as the article emphasizes, successful AI implementation still depends on foundational capabilities like data quality, cross-functional collaboration, and change management. It’s not enough to just plug in a new platform; companies who reap real benefits from today’s technology must ensure they align people, processes, and technology to make smarter decisions, faster. As more organizations learn how to operationalize AI effectively, those who invest in the right infrastructure and talent will gain a significant competitive edge in the years ahead.

CAPSTONE TAKEAWAY

AI isn’t replacing supply chain expertise at all: it enhances human capabilities and drives better decisions. At Capstone, we view AI as a tool to empower smarter decisions, not automate them away. Our teams use AI to improve labor forecasting, route optimization, and order visibility; but always in tandem with skilled operators and frontline expertise. As AI continues to mature, our focus remains on pairing tech innovation with people-first execution to deliver better outcomes for our customers.